Solution

Issue Issue

Cell manufacturing

for regenerative medicine

In recent years, there has been growing expectation that regenerative medicine, which uses a patient’s own cells, will be a new treatment method with the potential to cure diseases that have been difficult to cure until now.

In regenerative medicine, cells are cultured and multiplied, and then administered to patients in the desired condition and amount. In other words, cells are the raw material and also contain cells in the final product, and cells are manufactured at each phase of regenerative medicine research and development, clinical trials, and commercial production.

However, at present, the cost of cell production is high, and the price at which cells are provided to patients also remains high, so regenerative medicine has not yet become widespread. Although many promising regenerative medicine seeds have been developed, only a limited number have been put to practical use.

Necessity of

specialized personnel

Cells are living organisms and vary from donor to donor. For this reason, at cell manufacturing sites, work in a sterile environment and judgment by specialized personnel are essential for cell culture management and monitoring.

Because it is an analogue process, it is difficult to develop equipment or automate it, which leads to high manufacturing costs.

Therefore, we believe that in order to popularize regenerative medicine, it is necessary to have a method that enables anyone to easily and efficiently produce high-quality cell products and that allows for seamless transitions between the research and development, clinical trial, and commercial production phases.

Solution Solution

Achieving efficiency in cell manufacturing

for regenerative medicine

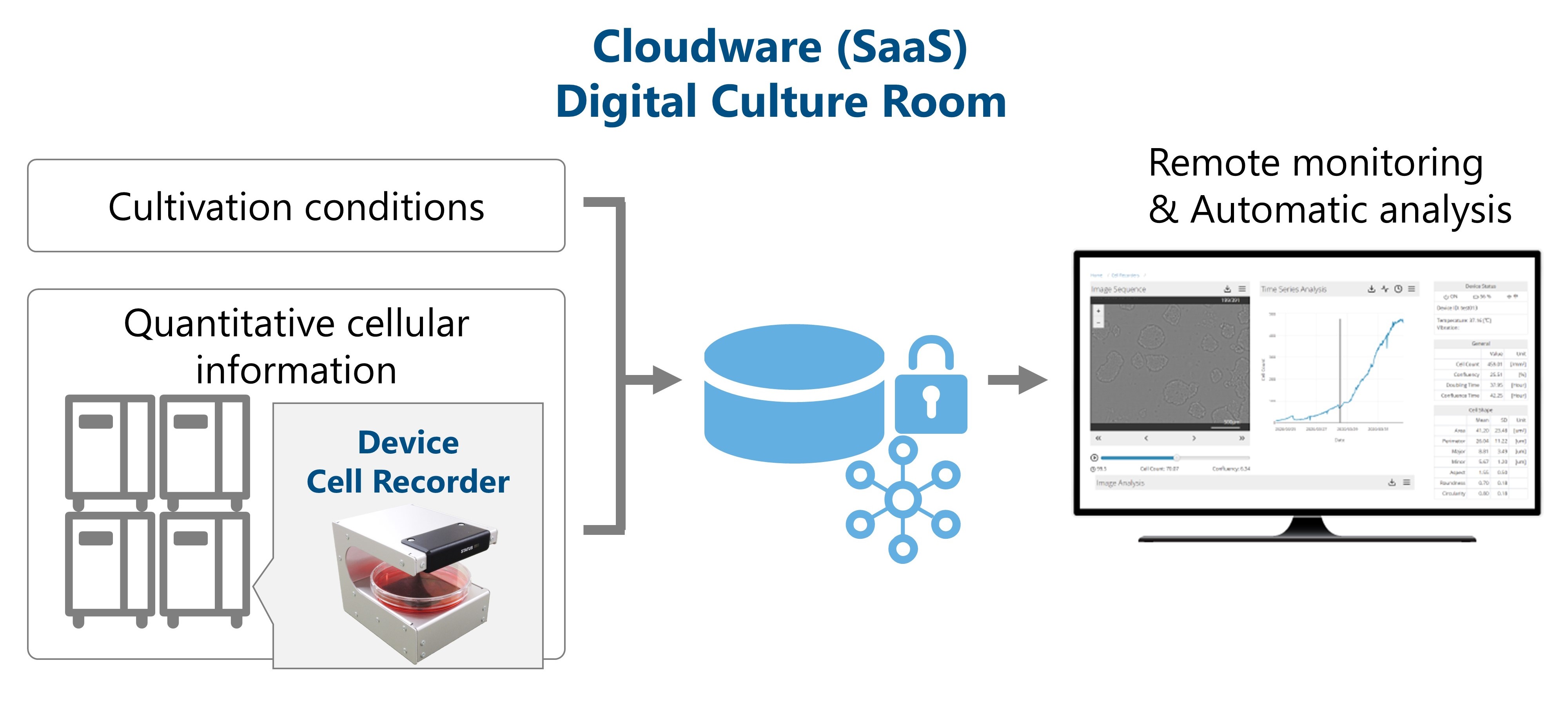

We aim to create a society in which promising regenerative medicine seeds are released one after another and provided to patients at reasonable prices, and we provide advanced cell management cloudware, smart frozen inventory management, and cell monitoring equipment that can be used from the research phase.

Quantitative information on cells and culture conditions

are collected on the cloud

Value

– Quantify cell proliferation and changes during culture

– Eliminate the need to enter the culture room (CPC) for confirmation

– Share data in real time with your team

Cell Recorder

A cell monitoring camera device

installed inside a CO2 incubator

Value

– World’s smallest class size, capable of multi-point measurement

– Cordless, easy to install in CO2 incubator

– Lineup to suit various containers

(T25-T225, 35-150mm dishes, well plates)

– IQ/OQ support, delivery possible in a decontaminated sterile bag

Achievements

– CPC/CPF:

Jikei University, Osaka University, etc.

We develop and provide products that can be used

in the commercial production phase.